Big Bag emptying stations

As a conveying technology specialist for bulk materials, we design solutions in the field of big bag handling individually geared to the needs of our customers. The big bag emptying stations for all types of big bags and bulk materials are designed in such a way that they can be seamlessly integrated into the production environment both mechanically and in terms of control technology. This makes it convenient to empty big bags.

Facts that will convince you

- Modular design for a high degree of customisation

- Efficient and user-friendly big bag changing

- Low-dust emptying

- Evacuation of emptied Big Bags

- Integration into the production environment

- Control engineering and system integration

- ATEX version

- Design in steel and stainless steel

- FDA in compliance with Regulation (EC) 1935/2004

- Various components for optimising outflow

- Special versions possible

- Pneumatic and mechanical product conveyance

- Wear protection for abrasive products

Product description

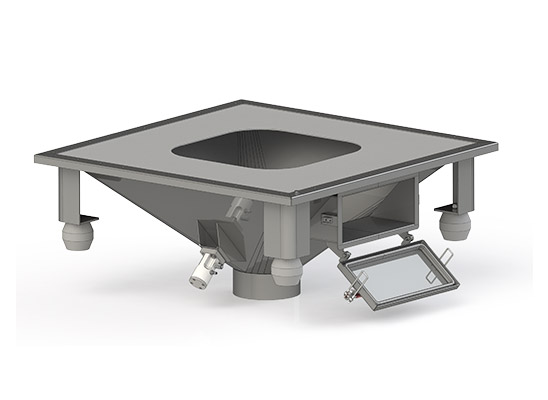

The big bag emptying stations are suitable for all disposable and returnable big bags and for big bags with film linings. They are suitable for use for varied, granulated, poorly-flowing, bridging, dusty and abrasive powders and granulates.

The main differences between the big bag emptying systems are the different loading systems, materials, surfaces, discharge aids and downstream peripheral systems for metering, conveying, mixing and sifting. These are tailored to your individual requirements.

Materials

The parts of the big bag emptying station that do not come into contact with the product such as frames can be made of stainless steel and painted or galvanised steel. The elements that come into contact with the product are made of bright rolled 1. 4301 (V2A) as standard. Other materials can also be used upon request.

For the food industry, the surfaces and seals that come into contact with the products are designed in accordance with Regulation (EC) 1935/2004. We can provide components with increased wear protection for use in building materials companies.

Functional description

Inserting big bags into the emptying station

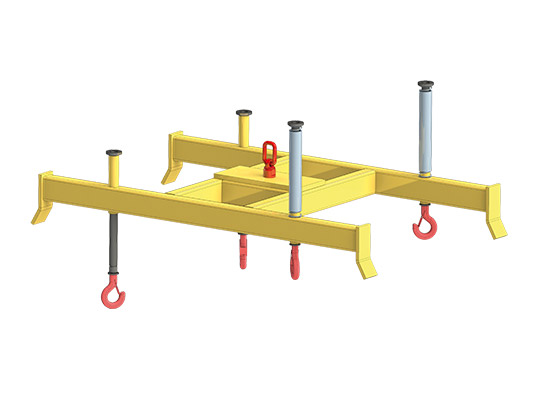

The operator positions the crane or forklift cross member above the big bag that is to be emptied and attaches the big bag loops to the holding eyelets provided. The big bag and the cross member are then moved into the emptying station using a crane, a forklift or a different industrial truck and set down on the frame.

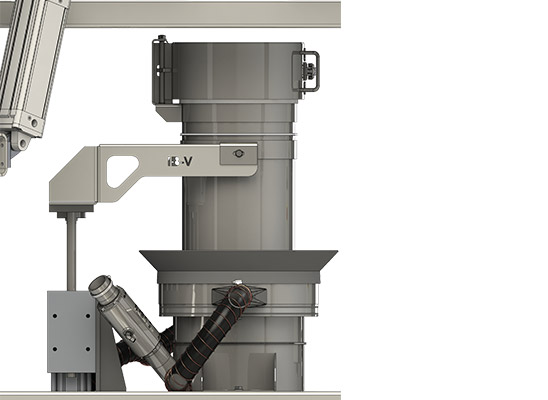

Connecting the big bag

The big bag’s discharge hose is pulled over the inflation sleeve (shown in black on the illustration). The half-shells are then closed and locked. A purely pneumatic or electrical controller is then used to inflate the inflation sleeve. This attaches the discharge hose to the pipe. If you are using an emptying connection with a mechanical clamping lid, this is also attached. This also reduces dust escapes significantly.

Product metering

The material is generally metered and conveyed using cellular wheel sluices, conveyance and metering screws, and the pneumatic conveyor. In order to protect downstream conveyance and metering devices, as well as production, from foreign objects, a protective screen can be installed below the big bag emptying station.

In order to safeguard production, the emptying system can be equipped with a fill level sensor as a MIN indicator. The material column is therefore monitored and a big bag replacement can be detected and implemented in good time.

Downloads

Our individual customer solutions in the Big Bag handling sector

Our big bag emptying systems differ as much as our customers’ requirements and almost always have an individual note. Each big bag system is therefore unique.

We can use system modules to offer, design and produce numerous solutions quickly and in a reproducible manner. Furthermore, our range of modules increases continuously due to the requirements of our new customers.

The references section provides you with a selection of customer projects that have already been completed, along with notable special features.